Input values in the form above, to find out: the number of lockers required (if sourcing traditional lockers), the number of lockers required (if sourcing smart lockers), the number of lockers saved (if sourcing smart lockers) and the total space saved if sourcing smart lockers.

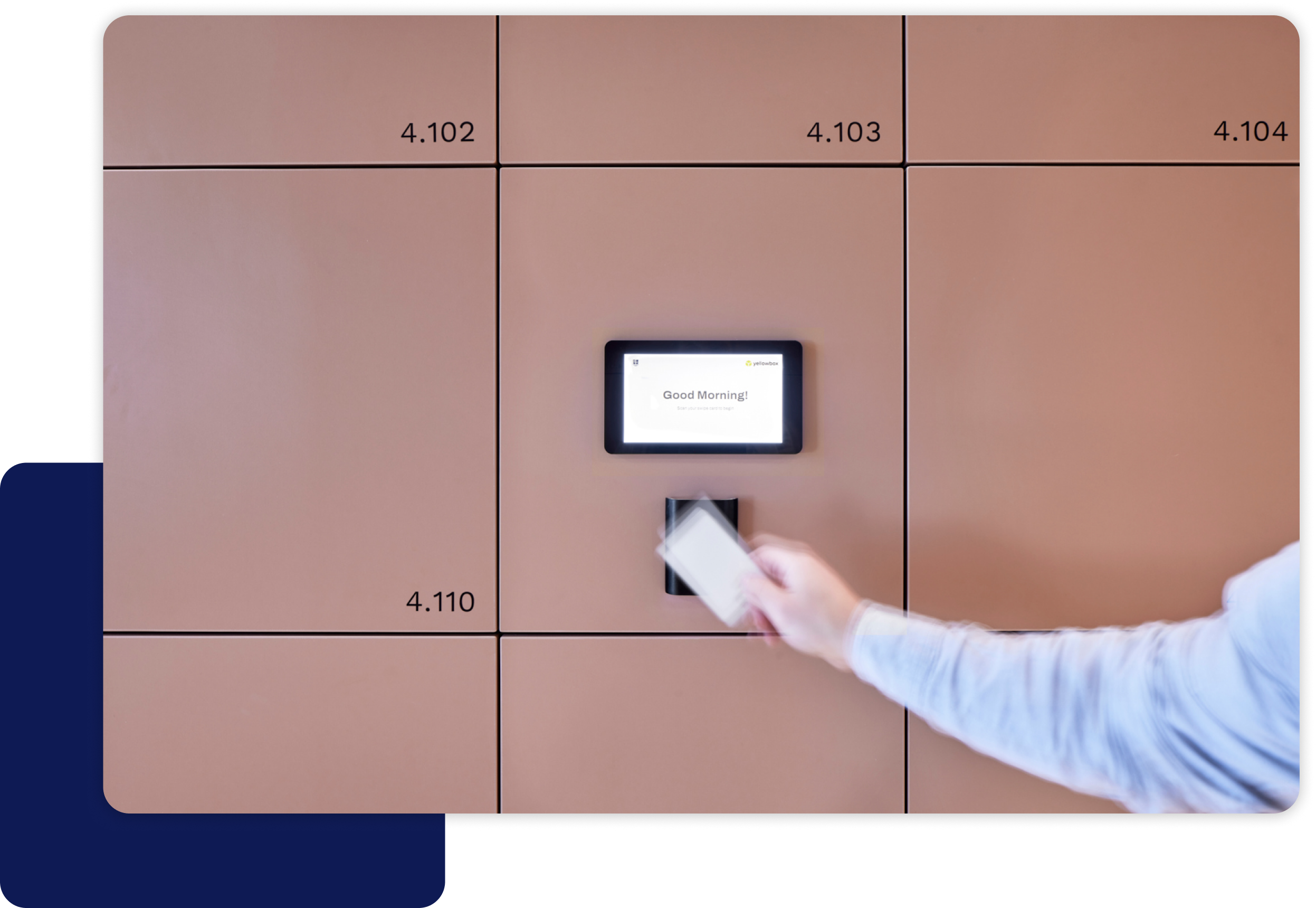

Our data suggests that 20-30% of employees (depending on the hot desking and clean desk policies in place) don't require a locker on a regular basis. Smart locker systems such as Yellowbox, provide hot locker settings that can be applied to e.g. 10% of your lockers. This saves on the number of lockers required to service your entire headcount and account for any growth.

Upfront ROI, or Capital Expenditure Savings are determined by the reduced amount of lockers required with a smart locker system.

Upfront ROI = [# of Lockers Required Sourcing Traditional Lockers - # of Lockers Required Sourcing Smart Lockers] * [Cost of Locker]

Ongoing ROI per annum, or Operational Expenditure Savings are determined by the rent saved on requiring less lockers and savings in administration time.

Requiring less lockers doesn't only provide an captial expenditure saving, it also provides an operational expenditure saving, with less space required.

Non-smart lockers e.g. key or code lockers, require constant manual tracking and allocation, especially during times of high turnover.

Ongoing ROI per annum = [Saved Rent per Annum] + [FTE Cost Savings per Annum]

Saved Rent per Annum = ([# of Lockers Required] - [# of Smart Lockers Required]) * [Space Required per Locker] * [Office Rent per sqm per Annum]

FTE Cost Savings per Annum = ([Facilities / Workplace Manager Salary per Annum] * [# of Lockers Required] * [% of FTE Required to Manage a Traditional Locker per Annum]) - ([Facilities / Workplace Manager Salary per Annum] * [# of Smart Lockers Required] * [% of FTE Required to Manage a Smart Locker per Annum])

Assumptions

FTE (Full-time Employees) required to manage 1000 non-smart lockers = 0.83

FTE (Full-time Employees) required to manage 1000 smart lockers = 0.17

Space required per locker (sqft): 0.6720

Space required per locker (sqm): 0.0625

The costs of administration and management of traditional lockers (e.g. key or code lockers) are typically overlooked when deciding upon office lockers.

For example, large organisations have had over 10 FTEs (Full-time Employees) managing over 10,000 traditional lockers. This reduced to only 2 FTEs managing the same amount of smart lockers.

Facilities and Workplace Managers need to consistently turn their focus onto managing lockers. Especially for the following situations:

New employee is onboarded

Existing employee exits the organisation

Employee moves to or from another building/team

An employee looses a key or forgets their code

Employee needs assistance in getting into their locker

Smart lockers provide automated and self-serve experiences for new and exiting employees. When integrated with access control and SSO, the system can automatically free up the locker of an employee exiting the organisation. Similarly, new employees already have an existing SSO account and integrated access control, which means they can book and use a locker without any allocation process.

24/7 support ensures employees and management are always provided expert assistance when faced with locker issues. Employees can be re-allocated a locker within three clicks, compared to the manual process of retrieving an employee's locker key, noting down which locker is now available, and to locate and provide the new locker key to the employee.

Avoiding the purchase and installation of one standard MDF office locker results in an estimated carbon savings of approximately 125 kilograms of CO₂-equivalent (CO₂e) — or about 275 pounds of CO₂e. This figure represents the average total emissions typically generated over the full lifecycle of a locker—from raw material extraction and manufacturing, to transportation, installation, and end-of-life disposal. The bulk of emissions come from producing the MDF panels and synthetic resins used in the locker, while local transportation and installation contribute only a small portion. Disposal emissions are also significant, particularly if the locker ends up in landfill, where methane from decomposing wood substantially increases its carbon impact.

The 125 kg CO₂e total (275 lbs) is composed of approximately 60 kg (132 lbs) from materials and manufacturing, primarily driven by the energy-intensive production of MDF and melamine finishes. Transportation contributes about 2 kg (4.4 lbs), assuming delivery via full truckload over a local distance. Installation adds around 1 kg (2.2 lbs), mostly from packaging waste and light tool use. Finally, disposal at end-of-life contributes roughly 60 kg (132 lbs), based on a mix of regional waste methods, with some lockers incinerated (releasing biogenic CO₂) and others landfilled (producing methane emissions). These stages combine to form a realistic, regionally blended estimate of the locker’s carbon footprint.

To put this into perspective, saving one locker is roughly equivalent to driving 500 kilometres (or 300 miles) in a petrol car, charging over 15,000 smartphones, burning 14 gallons of gasoline, or cutting out one month of meat consumption for a single person. When considered at scale—across entire office floors or building projects—this offers a clear opportunity to reduce embodied carbon through leaner, more efficient storage design. It’s a tangible way for workplaces to align fit-out decisions with broader sustainability goals.